- About Us

- Quality Policy

Quality Policy

Individual accomplishes the work in compliance with the standards from start; providing our customers with competitive products through constant improvement and quality enhancement in a timely fashion.

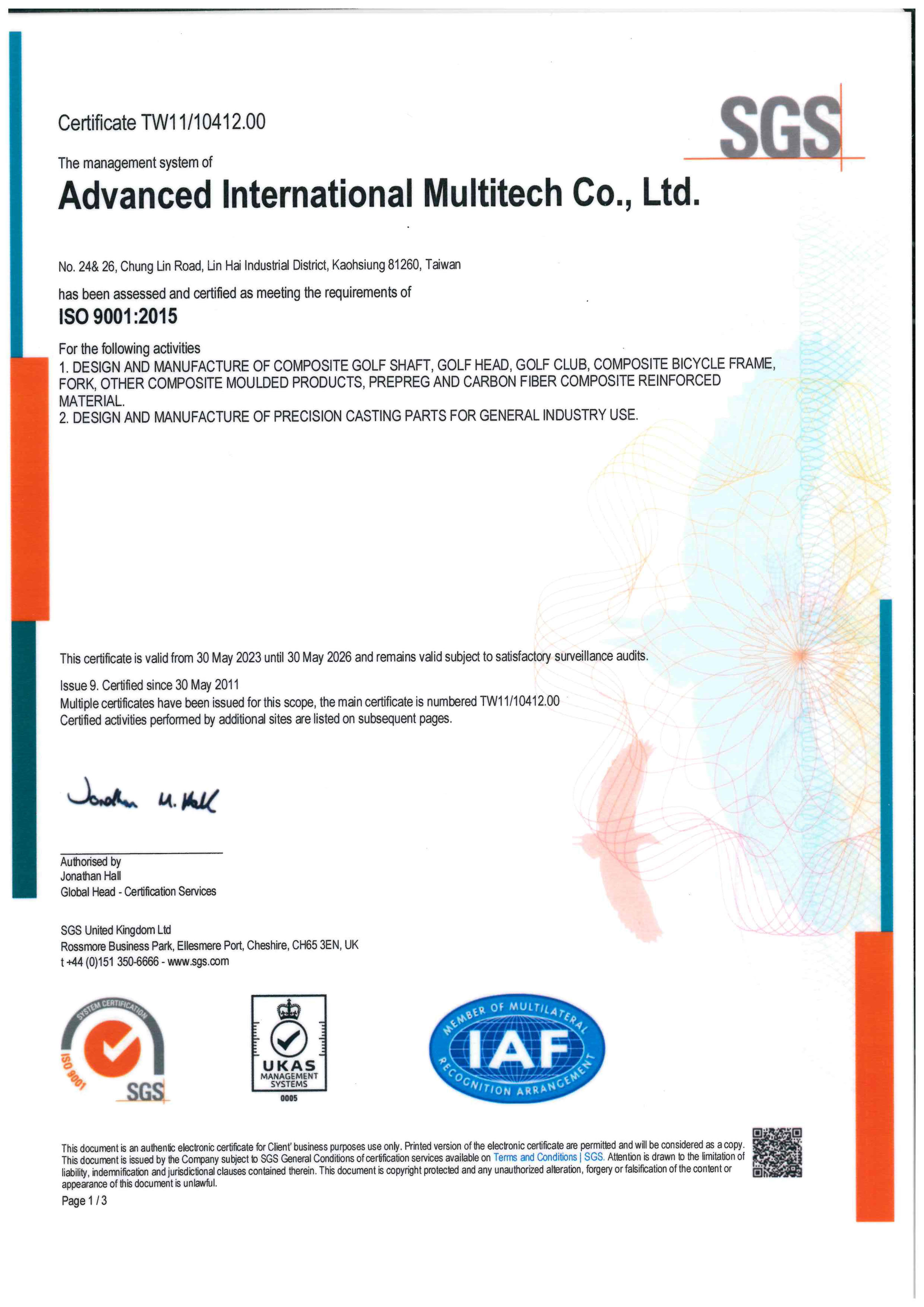

ISO 9001

Effective Date

2023/5/19~2026/5/30

Original Certification Date

2011/5/30

20241215reissue.jpg)

AS 9100

Effective Date

2023/3/11~2026/3/10

Original Certification Date

2014/3/12

.jpg)

ISO 14001

Effective Date

2024/11/25~2027/11/21

Original Certification Date

2006/11/22

.jpg)

ISO 45001

Effective Date

2024/12/04~2027/09/12

Original Certification Date

2018/11/12

Implementing QCC, TPM improvement activities and lean production to strengthen work efficiency and quality

In order to improve quality and satisfy customer requirements, AD Group has been devoted to quality and manufacturing process improvements. By regular QCC, lean production, TPM outcome demonstrations, we encourage all employees to exert creativity and share improvement accomplishments.

QIT and lean production are companywide activities; aim to enhance job performance and improvements from top to bottom.

QCC & TPM are activities which involve front-line workers to form small groups, to improve qualities on their works or equipment they use; these are activities will indicate self-motivation and improvements from bottom up.

QCC & TPM are activities which involve front-line workers to form small groups, to improve qualities on their works or equipment they use; these are activities will indicate self-motivation and improvements from bottom up.